In industrial LiDAR systems, the laser is one of the core components. It determines the performance of the radar, including measurement accuracy, detection distance, response speed, etc. Therefore, choosing the appropriate laser is crucial to ensure the efficiency and reliability of the laser radar. Here are several key factors to consider when choosing an industrial LiDAR laser:

1. Laser wavelength selection

The wavelength of laser directly affects the penetration, resolution, and reflection performance of laser radar on different objects. Common laser wavelengths include:

Near infrared laser (750-1500nm)This is the most commonly used wavelength range for industrial LiDAR. It can provide good penetration in various environments and has good reflection effects on most objects, especially in clear atmospheric conditions. Commonly used in applications such as object detection and distance measurement.

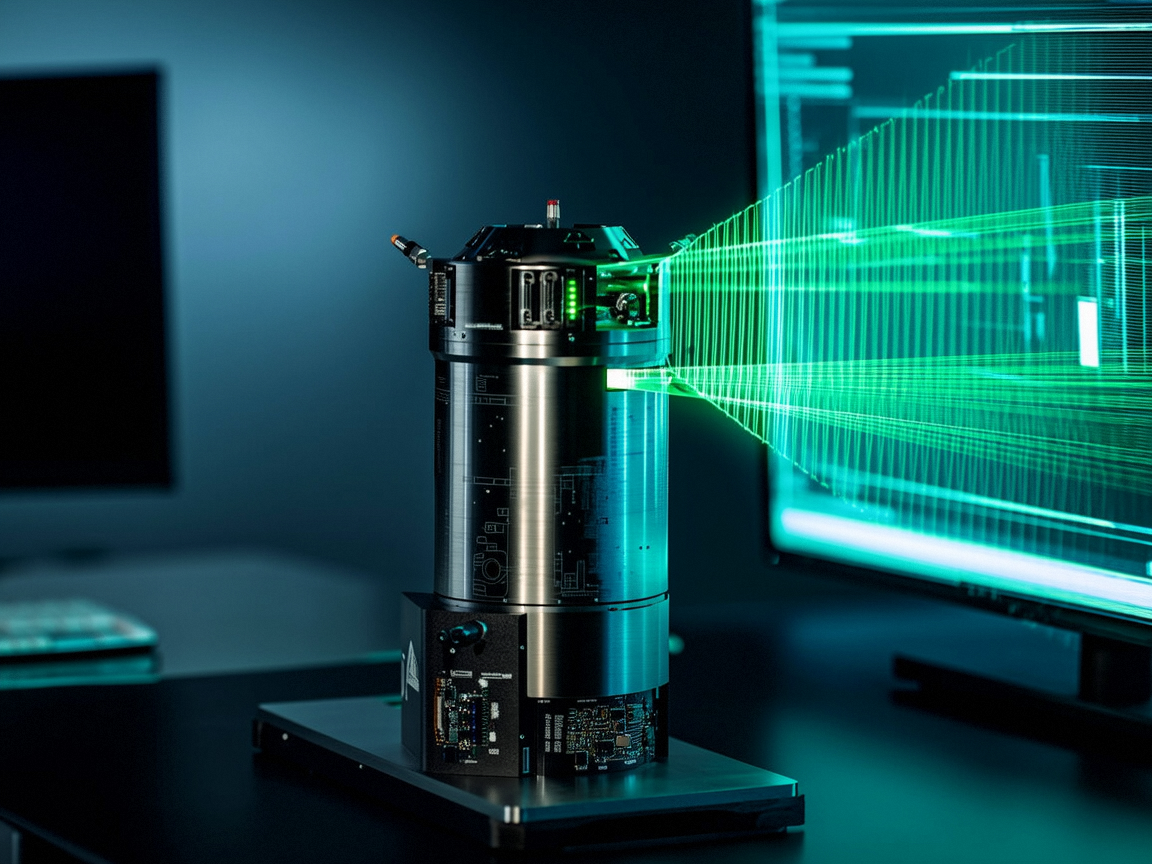

Short laser wavelength (such as 532nm green light)Short wavelength lasers are suitable for scenes that require high precision and detail capture, and can better reflect small particles and object surfaces, making them suitable for tasks that require high resolution.

Long wavelength laser (such as 1550nm)Long wavelength lasers have strong penetration ability into the atmosphere and can effectively reduce the impact of atmospheric scattering, making them suitable for long-distance detection and applications in harsh environments.

The power of the laser determines the intensity of the laser beam, which in turn affects the measurement distance and signal strength of the laser radar. In industrial applications, it is very important to choose a laser with the appropriate power:

low power laserSuitable for precise measurement at close range, commonly used for object detection in smaller work environments or spaces.

high power laserSuitable for long-distance detection, able to penetrate even farther distances, suitable for large-scale environmental scanning, such as road mapping or laser radar systems in high-altitude flight.

pay attention toThe power and usage scenarios of industrial lasers should comply with safety regulations. Excessive power may pose safety risks, especially in environments with personnel present.

The laser of LiDAR can use different modulation methods to improve ranging accuracy. Common modulation methods include:

Pulse ModulationIn this way, the laser emits short pulses, each with a short duration (usually in nanoseconds), suitable for long-distance measurements and providing high-precision time measurements.

Continuous Wave Modulation (CW)In this way, the laser continuously emits laser and measures by comparing the phase difference between the emitted and received signals. Suitable for applications with high precision and real-time feedback requirements.

Industrial environments often have harsh working conditions, such as high temperature, humidity, dust, etc., so the stability and durability of lasers are the key to selection. Choosing lasers with high stability, high temperature resistance, corrosion resistance, and strong vibration resistance can effectively improve the performance and lifespan of laser radar.

The scattering angle and directionality of laser determine the field of view and measurement accuracy of radar. An ideal laser should have a small divergence angle, allowing the laser beam to maintain a highly concentrated characteristic over a long distance, ensuring high-precision measurements.

When choosing a laser, in addition to technical performance, its economy also needs to be considered. The manufacturing and maintenance costs of different types of lasers vary. Choosing a laser with appropriate cost-effectiveness can ensure performance while controlling overall costs.

Choosing the appropriate laser is the key to the successful implementation of industrial LiDAR systems. It is necessary to comprehensively consider factors such as wavelength, power, modulation method, stability, durability, and cost of the laser, and make a choice based on specific application requirements. For example, long-range, high-precision LiDAR systems may prefer to choose lasers with higher power and longer wavelengths, while for short distance, fine detection applications, lower power and shorter wavelength lasers can be selected.

Choosing the appropriate laser according to practical application needs can maximize the performance and reliability of the laser radar system.

Contact us feel free to call or write anytime, We will call you back soon!